Industry News

Freshness Keeper New Utility Model : A Rectangular shape Food Storage Container with Good Sealing

Field of Technology

The utility model relates to the technical field of portable tableware, in particular to a baby food containers.

Background technique

Dinnerware or tableware containers are used for distributing or ingestion of food. In daily life, we have encountered and used a variety of tableware. With the improvement of people's life quality, people have certain requirements for the use of food containers, which can give people a high experience while enjoying food.

At present, the traditional food containers used to hold some cold drinks are relatively simple, which is only made of a simple box and a box lid. This kind of cold drink containers with simple structure, especially when children or infants are used, needs the assistance of other tableware utensils to eat the food in the box, and for those at the bottom of the box, it is relatively troublesome to eat, which makes the convenience low.

Content of Invention

In view of the shortcomings of the prior art, the Freshness Keeper utility model aims to provide a baby food container which is very convenient to use, suitable for various age groups, with good portability and relatively high safety.

To achieve the above purposes, the utility model provides the following technical solutions:

1.A baby food container comprises a box body and a box cover arranged on an opening of the box body. A mounting mouth is provided in the middle of the box bottom of the box body, and a soft rubber bottom is arranged on the mounting mouth. The installation port is provided with an annular wall type convex one, the convex one is provided with an annular equal diameter cavity from top to bottom, the inner diameter is gradually reduced from top to bottom neck cavity, annular equal diameter cavity two, the outer edge of the rubber soft bottom is provided with an equal diameter cavity one, neck cavity, equal diameter cavity two matching convex two.

2.The utility model is further arranged as follows: an open edge of the box body expands outward to form a flanging part, and a cover closing part is arranged on the box lid which is closely matched with the cover closing of the flanging part.

3.The utility model is further arranged as follows: an annular mounting ring is arranged on the inner end face of the box cover, and an interval is provided between the outer side wall of the mounting ring and the inner cavity wall of the container body.

4.The utility model is further arranged as follows: a soft sealing ring is fixed on the lower end surface of the mounting ring, and the outer edge of the sealing ring is tightly arranged between the inner cavity wall of the box body after the box cover is closed with the box body.

5.The utility model is further arranged as: the middle part of the box cover is concave downward and a mounting cavity is arranged on one side of the bottom of the mounting cavity.

6.The utility model is further arranged as follows: The central part of the bottom cavity of the mounting chamber is provided with two intervals of the hinged seat, the two hinged seat is hinged with a hinged shaft, the hinged shaft is installed on the opening plate, the opening plate and the position corresponding to the air vent is provided with a sealing column, sealing column with the opening plate to the direction of the air vent displacement can make the lower part of the sealing column inserted into the air vent and sealed between the air vent.

7.The utility model is further arranged as follows: the air vent is provided with a sealing sleeve, and the lower part of the sealing column is inserted into the air vent and sealed with the sealing sleeve.

8.The utility model is further arranged as follows: a limit plate is arranged on the opposite side of the opening plate and the sealing column downward, and the height of the limit plate is less than the height of the sealing column.

By adopting the technical scheme, the technical effect of the utility model baby food containers is as follows: By setting a soft rubber bottom at the bottom of the container, then when eating soft food, you can gently push up from the bottom, you can make the delicious food in the box body rise up, which makes the use very convenient, can be suitable for all kinds of age groups, portability is good, the use of safety is relatively high.

Attached drawing description

The utility model baby food containers is further explained in detail in combination with the attached drawings.

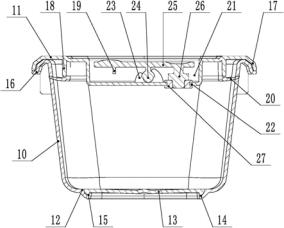

FIG. 1 is the schematic diagram of the profile structure of the baby food containers utility model.

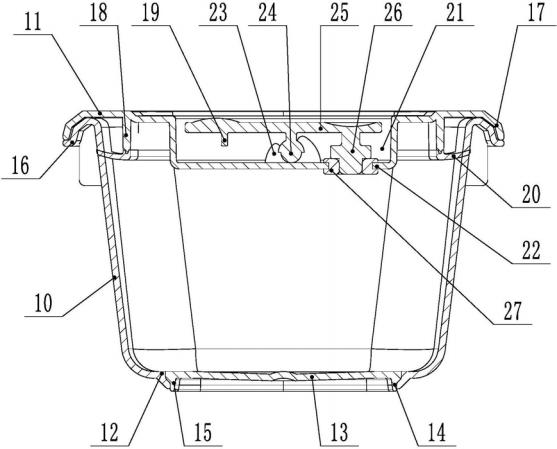

FIG. 2 is a schematic diagram of the three-dimensional structure of the container body of the utility model.

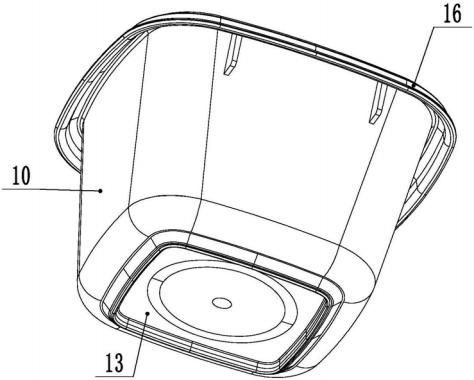

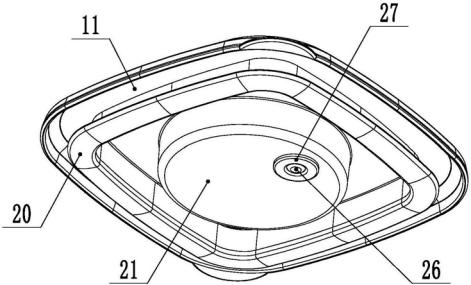

FIG. 3 is a schematic diagram of the three-dimensional structure of the container lids of the utility model.

Specific mode of implementation

Referring to FIG. 1 to 3, a portable baby food container disclosed by the utility model comprises a box body 10 and a box cover 11 arranged on the opening of the box body 10, and a mounting port 12 is provided in the middle of the box bottom of the box body 10, and a rubber soft bottom 13 is arranged on the mounting port 12; The installation port 12 is provided with an annular wall type projection 14, the projection 14 is provided with an annular equal diameter cavity from top to bottom, the inner diameter gradually reduced from top to bottom of the neck cavity, annular equal diameter cavity two, the outer edge of the rubber soft bottom is provided with an equal diameter cavity a, a neck contraction cavity, equal diameter cavity two matching convex two 15.

The opening edge of the box body 10 extends outward to form a flap part 16, and a cover closing part 17 is arranged on the box cover 11, which is closely matched with the flap part 16 after closing; An annular mounting ring 18 is arranged on the inner end face of the box cover 11, and an interval is provided between the side wall of the mounting ring 18 and the cavity wall of the box body 10. The lower end of the mounting ring 18 is fixed with a soft sealing ring 20, and the outer edge of the sealing ring 20 is tightly arranged between the outer edge of the sealing ring 20 and the inner cavity wall of the box body 10 after the sealing of the box cover 11 and the box body 10.

Wherein, the middle part of the box cover 11 is concave down is provided with a mounting cavity 21, and one side of the bottom of the mounting cavity 21 is provided with an air hole 22; The central part of the bottom of the mounting cavity 21 is provided with two inter-spaced hinged joint seat 23, two hinged seat 23 is hinged with an hinged shaft 24, the hinged shaft 24 is installed with an opening plate 25, the opening plate 25 and the corresponding position of the air hole 22 is provided with a sealing column 26, The lower part of the sealing column 26 is inserted into the air vent 22 and sealed with the air vent 22. The air vent 22 is provided with a sealing sleeve 27, and the lower part of the sealing column 26 is inserted into the air vent 22 and sealed with the sealing sleeve 27. A finite position plate 19 is arranged on the side opposite to the sealing column 26 on the opening plate 25. The height of the limiting plate 19 is less than that of the sealing column 26. The setting of the opening plate, air hole and sealing column is mainly to facilitate the hot food such as hot drinks in the food containers can be the same as the outside air through the air hole, which can properly reduce the temperature, and in this process, the external impurities can be avoided as far as possible to fall into the food in the storage container.

Post time: Nov-25-2022